Catalyzed Varnish

For most projects that see routine use, my go to finish is a catalyzed varnish. In terms of durability, wear resistance, chemical resistance, and overall longevity, I have found nothing that matches it. With all of these benefits, it also boasts a considerable advantage in labor costs of applying polyurethanes and finishes.

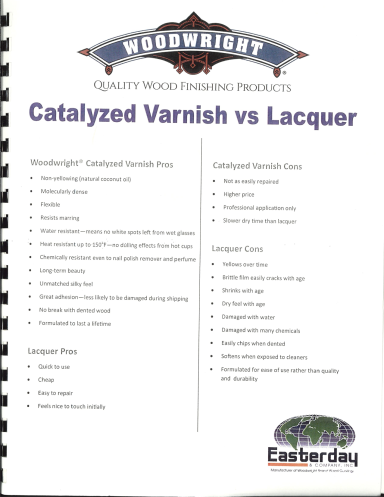

I have been very happy with results from Woodwright (specific product- ArmorVar 9938) and found the company to be professional, timely and intent on helping me get the best finish. Their stain selection tool allows you to visualize what various hardwoods will look like with a range of stains and finishes.

The results speak for themselves. Click on the image below to the left to view the durability of catalyzed varnish verses a number of solvents. Click on the image to the right for a list of advantages above a common professional finish, demonstrating the superiority of catalyzed varnish.

Hard wax oil

If being able to preform spot repairs in the future is important and doing so with a 0% VOC product, then hard wax oils may be a good option.

While there are many manufacturers and I have only worked with Rubio Monocoat, I have been very pleased with their system. View their website to see what their finish looks like on a variety of hardwoods. Here is a brief video explaining the application process with a couple minutes at the end showing how easy a spot repair can be.

Tung oil with citrus solvent

Tung oil is an age old finish that has been used on everything from exterior wood to boats and fine furniture. I only source 100% tung oil without metallic dryers. Tung oil cures naturally and seals and protects the wood below the surface. Citrus solvent thins the finish, allowing the tung oil to soak deeper into the wood fibers. This finish offers superior protection to moisture. Many finishes marketed as 'cutting board' finishes, such as mineral oil (a byproduct of the oil industry), do not cure - making for a softer surface and less water protection.

There are a few suppliers and Real Milk Paint has consistently delivered quality ingredients free of harmful additives.

Watch the video below to see four different species of wood transformed through the addition of tung oil and citrus solvent!

Milk Paint

One of the oldest, and safest, finishes is milk paint. Traditionally it utilized older milk and different forms of clay for the color. It provided UV protection. It has a vibrant range of colors and is a great choice for surfaces that little ones come into contact with.

This guide from Real Milk Paint provides more information about its history while this page provides a range of the colors they produce with this.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.